Everything You Never Wanted to Know About Lids and Bricks

To begin, this is the top side of the LSA supercharger:

The square area in the middle has a gasket that seals it to the intercooler brick inside the lid, the hot air enters the lid through the triangular opening through which you see the rotors, goes through the intercooler brick where it transfers heat into the coolant to be carried out and cooled by the heat exchanger.

This is the inside of the OEM CTS-V lid:

and this is that of the ZL1 Lid:

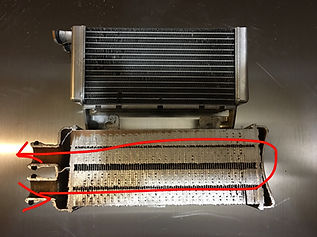

CTS-V brick vs ZL1 brick (both reinforced):

The ZL1 cover itself is a different design with a hump in the middle and smooth inside directing airflow into the runners vs the webbing inside the CTS-V lid.

As for the bricks, the CTS-V brick is thicker and has the mounting brackets on the sides in the way of airflow.

The intercooler consists of two cores, the coolant enters the bottom port, goes through one core, turns around in the end tank and goes through the other core before exiting through the top port.

The coolant inside the intercooler brick isn’t pressurized while the air inside the lid reaches positive boost pressure. This pressure differential causes the intercooler end tank to collapse and restrict flow.

This is a cutaway of a collapsed intercooler brick where you can see where the end tank will actually block the flow:

What does this cause? Here is a photo of the return flow into a trunk tank through a collapsed intercooler vs a straight one on the same car on the same day:

At what boost level does this happen?

Here is an example of a collapsed CTS-V brick from a car that was stock:

And another from a 2.55” upper pulley car:

What about the ZL1 lid? It is stronger due to a different location of the mounting brackets giving extra thickness to the sides of the end tank.

However, here is an example from a car that was running maybe 12psi for about 2k miles:

And another from a slightly higher boost level:

CTS-V Bricks With Fin Damage

Something we see quite a bit with CTS-V bricks is fin damage caused by heat and air flow. This is something we have yet to see with a ZL1 brick likely due to the higher fin density and better brazing